Eco C Stud Profile 70mm x 2.4m

Stud partition profiles are a low cost, high quality metal friction fit construction used to form the support frame for non-loading bearing plasterboard partitions.

Eco profiles are manufactured to the highest possible quality and fully conform with BS 7364: 1990. Specification foe galvanised steel stud work used in partitions with screw fixed plasterboards.

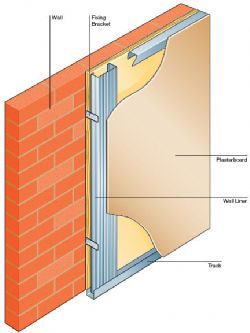

Method Of Build

The Eco U Track should be screw fixed to the floor along the line of the planned new partition. The head track should be fixed to the structural soffit vertically in line with the floor track.

The Eco C Studs should now be cut to the vertical height (less 10mm – to allow for any movementor disparity in the floor levels). Place the studs into the Eco UTrack and twist to lock into place. The open mouth of the C Stud should all face in the same direction. If you are intending to board out using plasterboard of 10mm thickness or less – the studs should be set out in the track at 40mm centres. If the board has a thickness of 12.5mm or greater – the studs should be set out at 600mm centres unless otherwised stated.

If insulation is specified, use insulation Hold Strips, screw-fixed or crimped to the studsprofiles 150mm from the partition head and at 1200mm vertical centres down the partition.

Movement control jointsmay be required to relieve nornmal structural movement without loading the partition. Movement control joints are required in partitions at intervals not exceeding 10m, where the partition crosses or abuts a strctural movement joint, and where partitions of dissimilar materials meet in the same plane.

The installation of electrical services should be carried out in accordance with the recommendations of the institution of electrical engineers. The knock-outs in the stud can be used for routing electrical and other small services. Cables should be protected by conduit or other suitable precautions taken to prevent abrasion when they pass through the metal frame.

When creating doorways within a partition wall we would recommend that full length stud profiles(with timber inserts where required) fixed to both floor and head track either side of the opening. Track profiles should then be cut and placed at the head of the doorway and fixed to each vertical stud on both sides.

The contractor should add a minimum of 5-7mm to both the overall width and height of the proposed door to allow for easier fixing and adjustmentof the door carcase. Where a heavy fire or acoustic door is required the method of construction may c hange, with heavier reinforcement than timber.

There are no reviews yet.